Single Line

Single Line

This project was developed with the support of Emeco, a company renowned for its sustainable aluminum furniture. Inspired by Emeco’s legacy of durability and simplicity, the piece explores an expandable chair structure—Single Line—using bent aluminum tubing and minimal components to ensure efficient manufacturing and timeless design.

Research

An in-depth study of Emeco was conducted to understand the company's values, design philosophy, and material focus. Emeco’s commitment to timeless, practical design is encapsulated in their statement:

“Aluminum was the obvious choice, engineered for practical purposes, designed to last.”

Inspiration

During a visit to Emeco’s facilities, many aspects of the manufacturing process were impressive, but the aluminum bending process left the deepest impact. This led to the conceptual direction of creating furniture from a continuous single line, inspired by the fluidity and structural clarity of bent tubing.

“Bending process”

“How about bending a single tube to create a frame?”

“Single line concept”

“What kind of frames could there be?”

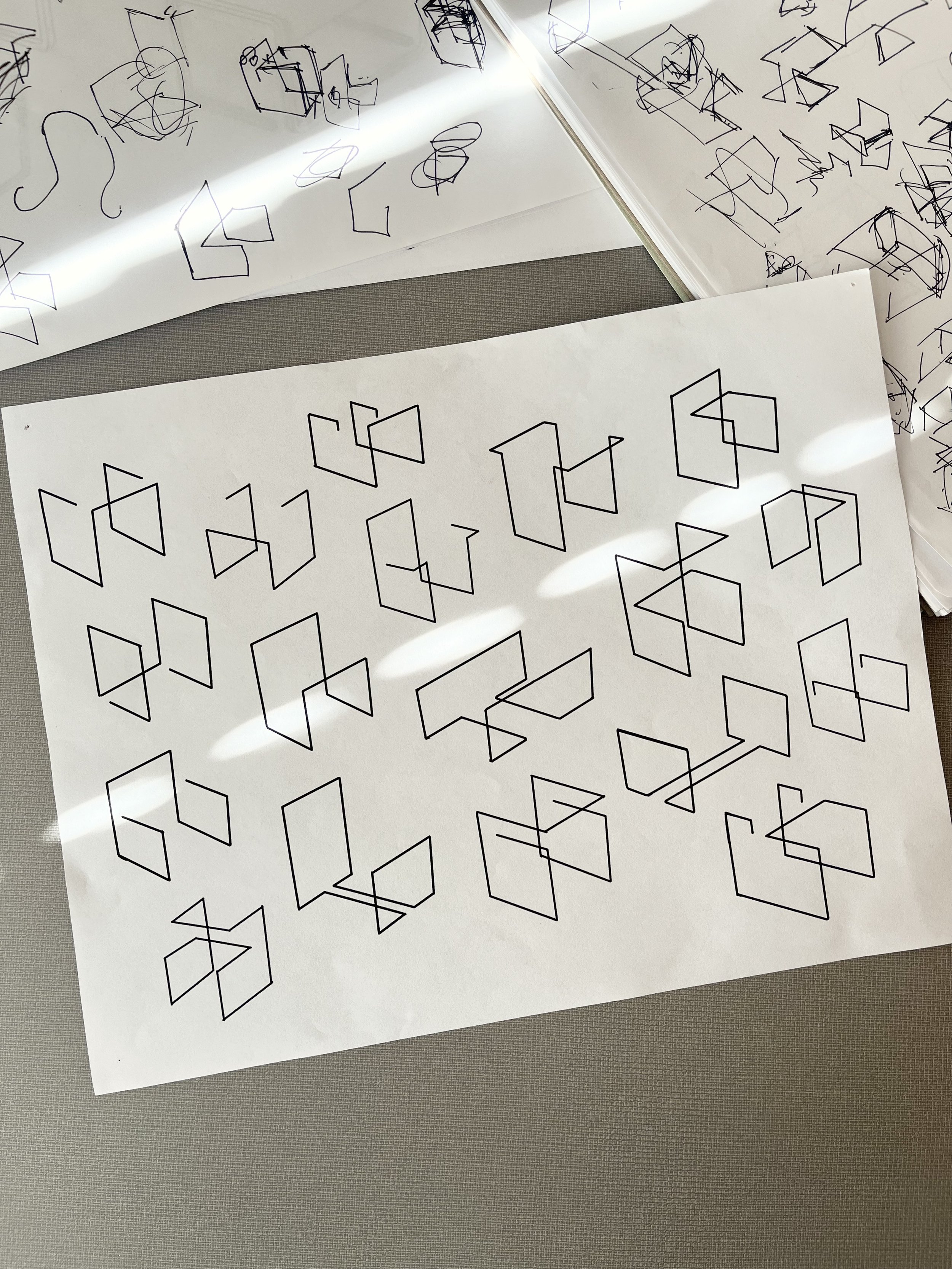

Ideation Sketch

Among various ideas and rough concepts, one direction was selected and further developed into a chair design. The focus remained on simplicity, manufacturability, and coherence with the “single line” theme.

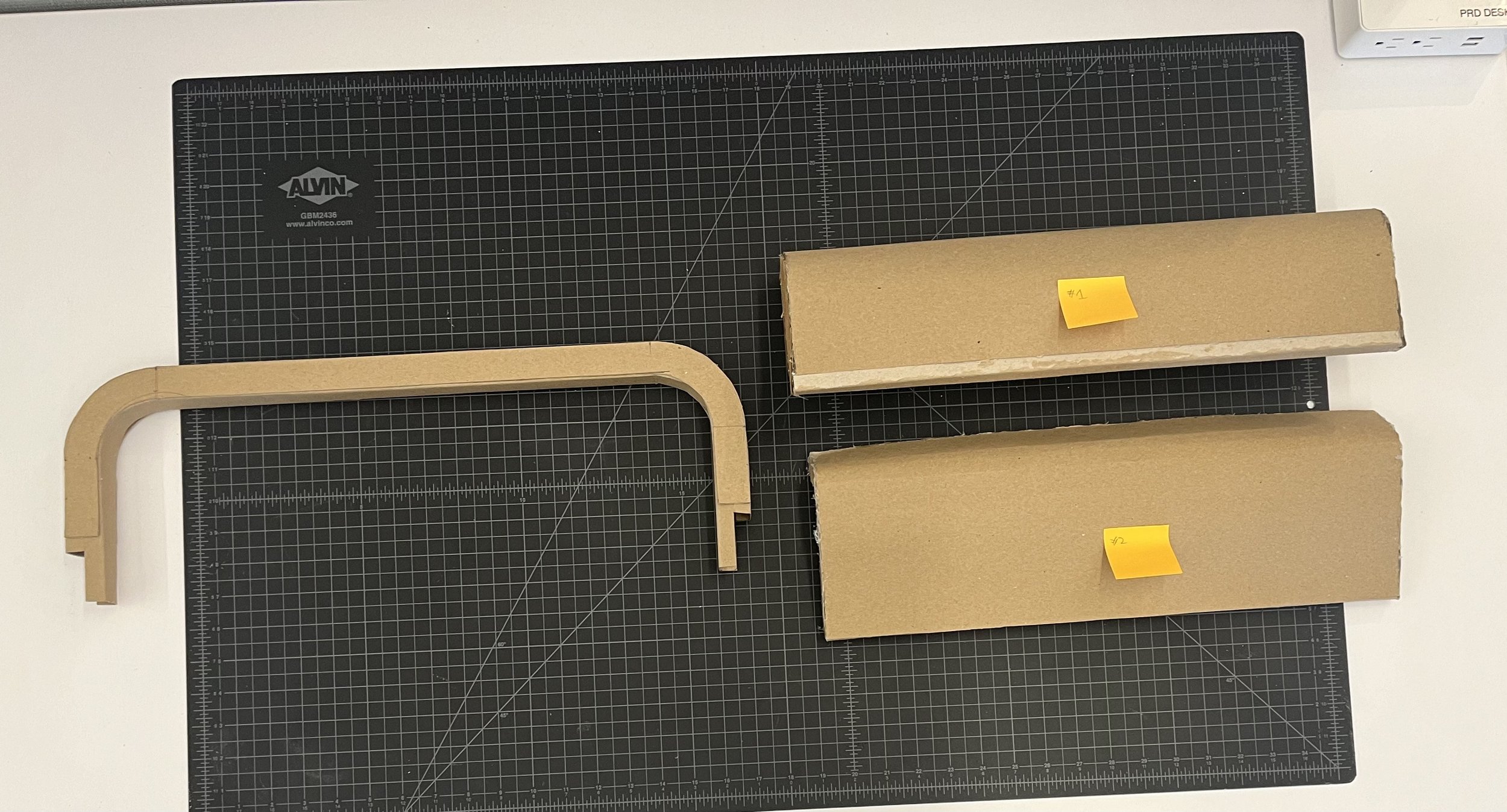

Prototyping

To validate two critical aspects of the design, a full-scale prototype was created and tested with users.

Backrest Grip Area

The seat pan and backrest form a continuous bent line. To assess grip comfort, two versions (a short and a long backrest) were created and tested.

“The short version was found to be more comfortable and intuitive to hold.”

Backrest Angle

Three variations of the seating angle were tested to determine optimal comfort.

“A 95-degree angle was reported as the most comfortable.”

Additionally, a quarter-scale model was produced using 3D printing to visualize proportions and structure.

Final Design

The Single Line collection includes a low-back chair, a stool, a two-seat bench, and a three-seat bench.

Features

Rounded corners:

The use of varied radii on all corners, a key element of the bending process, gives the design a soft, rounded aesthetic.

Plywood Edge Detail

The design highlights the exposed layered edge of the plywood, emphasizing material honesty and visual rhythm.

Logo Application

The Emeco logo can be applied to the wooden surface using laser engraving, offering a clean and durable branding solution.

Two Seatpan Options

A single seat structure accommodates two different types of plywood seat pans: Oak and Walnut, allowing for material variation.

Plastic Seatpan

A plastic seat pan version is also available, adding versatility and the potential for mass production.